Nearly identical to the Stylomine 303 accordion filler, but utilizing a normal straight sac segment with a compression spring to allow it to be compressed, and then expand on its own.

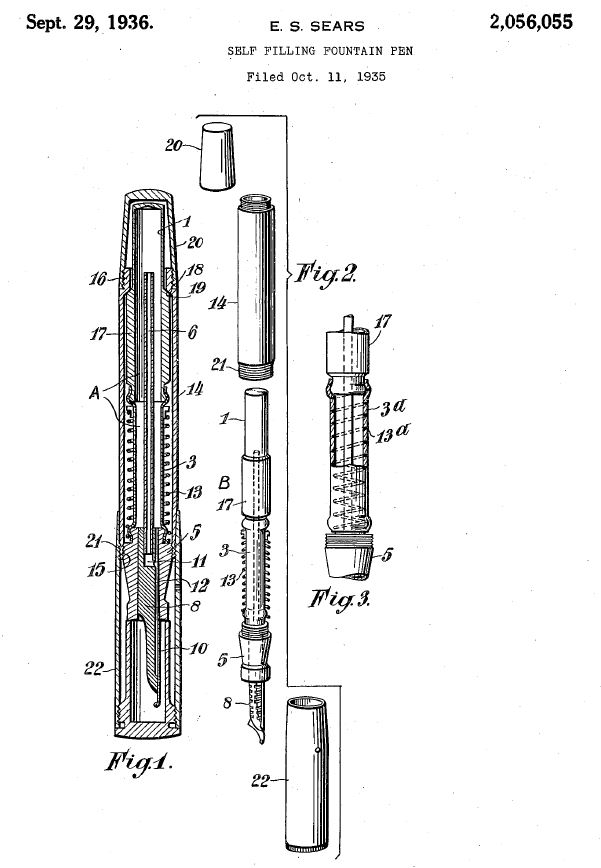

The Visofil V patented in 1934, likely released in 1935 in England, and possibly only sold for two to three years. This pen is also interesting because it is an unusual and improved variant of an accordion type filling system. The linear filling mechanism consists of three components: a tubular ink sac, a spring that fits over the sac portion of the unit, and a clear cylinder/button that contains the visible ink supply. I see the spring as an improvement because it compresses and expands the sac far more efficiently than an accordion sac would compress and expand on its own. The whole apparatus is situated inside the barrel with the button end of the solid hollow ink reservoir exposed and covered with a blind cap. Accordion replacement sacs are near impossible to find, but the pen was designed to utilize a standard sac cut into a tube. That an accordion style sac is not needed to work properly also adds a high degree of credibility to the filling system’s spring-assist function.

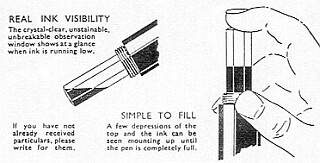

To fill the pen, remove the blind cap and depress the exposed button to compress the sac in the middle of the barrel. While the idea is a bit odd, the construction is fairly simple, and it works as well or better than other pump style fillers. The section and feed are typically constructed, with a long breather tube extending nearly to the end of the clear plunger to facilitate filling with repeat compression of the mechanism. The design has an added benefit of increasing ink capacity as the plunger button is part of the reservoir and fills nearly completely. The only other parts are a spring that surrounds the sac, and a small plastic washer to protect the sac from being damaged by the spring. Pictured is the assembled filling mechanism, and how it appears assembled within the barrel. The solid clear reservoir/button has an added touch of quality being machined into an octagonal shape matching the opening at the end of the barrel, thereby preventing the mechanism from twisting by either the user or twisting due to the action of compressing/releasing the internal spring.